Guang Dong Sunli Intelligent Logistics Equipment Co;Ltd

Contact: Mr. Du / miss Shaw

Tel:0769-88708222/85491680

Mobile:136 0028 2227

E-mail:sales@dgsunli.com

Fax:0769-85492858

address:Tangxia Village Industrial Zone, Gaobu Town, Dongguan, Guangdong

Automated logistics system based on reliable data sources and flexible control of the algorithm support, to automation, intelligent operations, reduce labor costs, improve efficiency, strengthen the level of information for enterprises to improve competitive advantage. Guangdong Shun Industrial Equipment Co., Ltd. has a mature automated logistics system development and implementation experience.

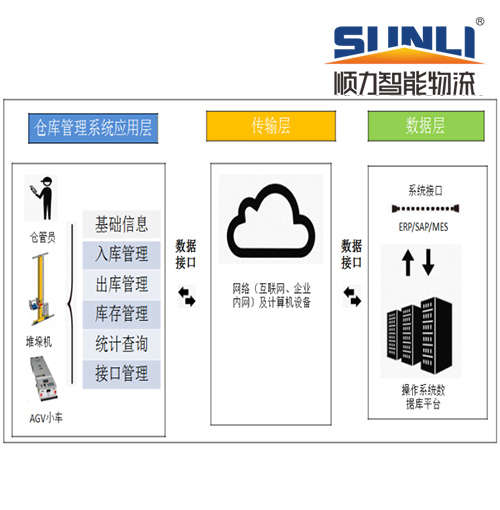

System Introduction - Shun Intelligent Warehouse Management System (WMS):

The intelligent warehouse management system is a modern operation management system based on electronic intelligent manufacturing management and warehouse management information. (JIT) as the theoretical basis, through the database technology, bar code technology, API technology and the corresponding communication mechanism and external system docking integration, can effectively manage the warehouse process and space to achieve batch management, fast access Library and dynamic inventory and so on.

Shun WMS warehouse management system module perfect

Including the following major modules:

Basic information management module:

1.WMS system through the data interface, Excel table, manual input, etc. to obtain basic user information, basic material information, supplier information, customer information, unified management of basic information, easy to query, add and deal with.

2.WMS system can be bar code technology, manual entry, etc. to obtain warehouse information, warehouse information, tray information, intelligent control of materials out of storage action.

Inbound management module:

(PC, PDA), which mainly includes: storage document management, storage with the disk, storage task management, empty disk into the storage system, Library.

Out of the library management module:

The library includes two versions of the user interface (PC, PDA), including: out of the library document management, out of the library with the disk, the library task management, empty out of the library Library, out of the library view.

Inventory management module:

1.WMS system provides intelligent, flexible and diverse inventory (regular inventory, designated material inventory), combined with a variety of measurement methods (such as: counting margin method, the number of absolute difference method, the amount of money margin offset offset method, etc.) The accuracy of the inventory data;

2. The use of mobile handheld terminal PDA inventory, automatically generate inventory reports, WMS system in the disk surplus, disk deficit account operation, the system automatically docking ERP update data, inventory efficiency is higher;

3.WMS system through the intuitive position map can simply understand the storage situation.

Statistics Query Module:

Statistics query mainly includes: inventory details query, inventory statistics query, inventory running account inquiries, out of the pool summary of statistical inquiries, system log inquiries, cargo statistics inquiries.

Data interface module:

1.WMS and SAP, Kingdee, UF and other ERP seamless docking, real-time interactive data;

2. All materials involved in the transaction records can be seamlessly with the ERP to achieve automation, to complete all the material transaction operations;

3. Through real-time data acquisition time to ensure that the physical and account consistency, improve the operation of ERP results;

4. Through real-time data collection and ERP delivery, greatly enhance the efficiency of warehouse operations, improve data accuracy, reduce staffing;

5.WMS system and customer existing production management system (MES) can be seamless docking, real-time sharing of production data;

6.WMS through the online function module, with most of the test equipment online, improve the IQC material inspection speed, test data automatically generate reports, cancel the paper report, to achieve paperless operations.

The advantages of the WMS warehouse management system:

1. Shun WMS warehouse management system is the integration of warehousing operations as the main goal of the system, to solve a variety of automation equipment, information systems integration and optimization issues. WMS system in addition to the results of management warehouse records, check and management, the biggest function is the warehouse operation process guidance and norms. Not only to deal with the results, but also through the operation of the instructions and norms to ensure the accuracy of operations, timeliness and related records of data automatically enter, increase the efficiency of the warehouse to enhance management transparency and reduce costs.

2. Data collection in a timely manner, the process of precision management, fully automated intelligent guidance, through the bar code management can significantly reduce the staff check, inventory work, improve work efficiency, and ultimately reduce staffing;

3. Precise location management, comprehensive state monitoring, make full use of limited warehouse space, greatly improving the utilization rate of warehouse volume;

4. The goods shelves and shelves, all intelligent by FIFO (or according to customer needs to develop the upper and lower frame strategy) automatically allocated upper and lower shelf location, to avoid human error;

5. Flexible and diverse inventory and inventory early warning function, real-time control of inventory, reasonable to maintain and control business inventories;

6. Through the automatic collection of batch information to ensure that the FIFO, to achieve the product production process of traceability of materials;

7. More importantly, the bar code management to promote the transformation of corporate management model, from the traditional rely on experience management to rely on accurate digital analysis and management, after the management into a management, real-time management, speed up the cash flow, Supply chain response speed, which will enhance the company's overall competitiveness.