Guang Dong Sunli Intelligent Logistics Equipment Co;Ltd

Contact: Mr. Du / miss Shaw

Tel:0769-88708222/85491680

Mobile:136 0028 2227

E-mail:sales@dgsunli.com

Fax:0769-85492858

address:Tangxia Village Industrial Zone, Gaobu Town, Dongguan, Guangdong

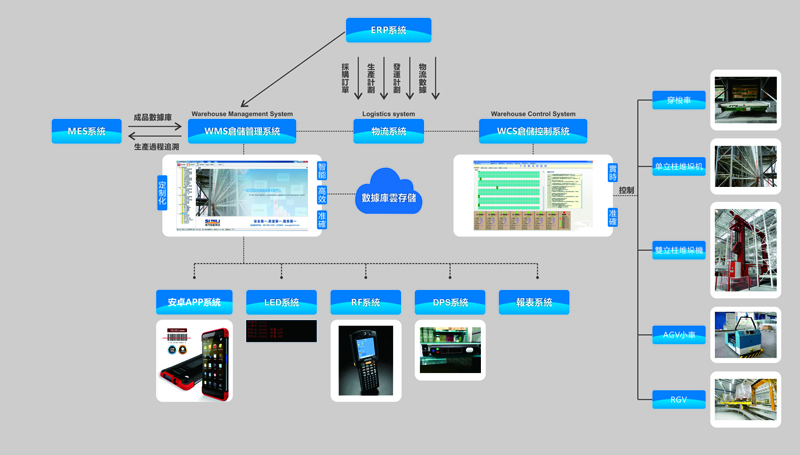

2.1 warehousing management system

1. Shun WMS Warehouse Management System is a modern intelligent operation management system based on electronic intelligent manufacturing management and warehouse management information. (JIT) as a theoretical basis, through the database technology, bar code technology, API technology (application program interface) and the corresponding communication mechanism and external system docking integration and quickly help the enterprise's warehouse management personnel on the inventory of goods into the The use of warehouse storage space, improve the efficiency of enterprise warehouse storage space and enterprise material management quality and efficiency, improve the level of warehouse management And production efficiency, to achieve material error prevention and trace management, reduce business inventories and labor costs, enhance the market competitiveness of enterprises to meet the changing needs of the supply chain to achieve a sound enterprise warehouse

2.2 level library management system

The warehouse management system (WMS) is a comprehensive management system through the material storage shelves, the order distribution, the material sampling, the inventory management, the system basic information management function management system, effectively controls and tracks the business process and the whole process of cost management , To achieve a sound enterprise warehousing information management. The system can independently perform inventory operations, in combination with other system documents and vouchers, to provide a more complete and comprehensive business process and financial management information. Combined with the customer's existing manufacturing system, through the interface and the existing manufacturing system interaction, enhance the level of information technology throughout the enterprise. The use of forklifts, shuttle cars and other equipment in a low-cost environment to achieve maximum efficiency, saving labor costs.

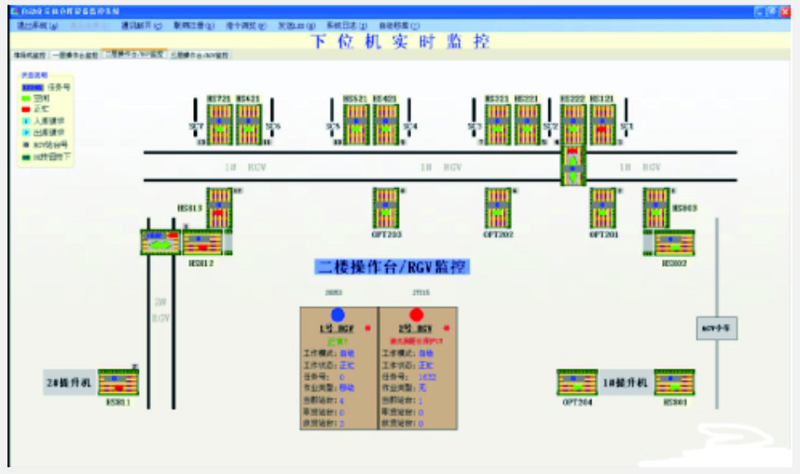

2.3 storage control system

WCS Abbreviation for Warehouse Control System. WCS is a layer between the WMS system and PLC system management and control system. On the one hand it interacts with the WMS and the system, accepts the instruction of the WMS system, and sends it to the PLC system, thus drives the library and the transmission equipment to produce the corresponding mechanical action. On the other hand, it will PLC system status and data in real time reflected in the interface, to provide the PLC system and the transmission line manual debugging interface

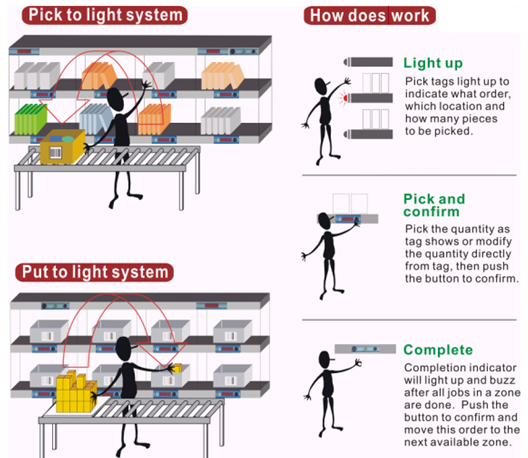

2.4 electronic tag picking system

The DPS electronic tag picking system is a set of electronic tag devices installed on the shelf, controlled by the computer and software, by the lights and digital display as an auxiliary tool to lead the picking staff correct, fast and easy to complete the pick Cargo work. DPS picking system can control the picking process flexibly, and real-time monitoring of the picking situation of the scene, and can reduce the picking error rate, speed up the picking speed, eliminating the inconvenience and waste of the form operation, and save some manpower Resources, so that you smooth the flow, happy to picking.

1, DPS electronic sorting system application prospects:

Electronic tag used in the logistics industry, can effectively improve the efficiency of sorting of goods, adapted to a single small amount of the library and the high frequency of the material, especially in the sorting and distribution of scattered goods with other sorting methods can not be compared to the advantages, In the commercial chain, drug distribution, distribution centers, electronic assembly, frozen products, audio and video products and other industries have a wide range of applications.

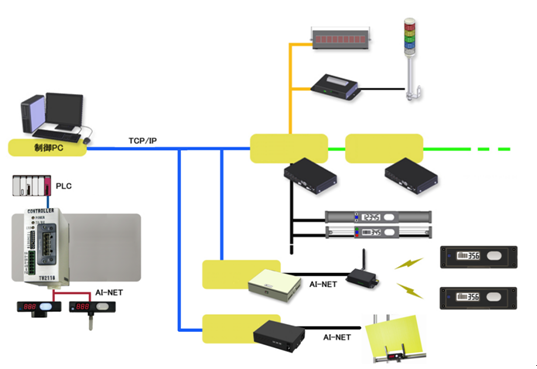

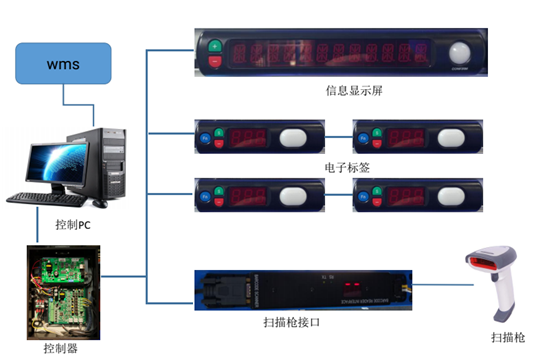

2, the system hardware architecture:

A, the system network map:

B, system structure

All the electronic tag components are connected with the controller, the controller connected to the DPS private network (independent network segment) switch, DPS control computer with dual network card, one end of the DPS private network connected to the switch, one end connected with the WMS communication network.

3, DPS sorting system selection strategy sub-picking and seeding: